![[New product launch] EasyNTC Adsorption Needle Aging Instrument, Say Goodbye To The Single Needle Suffering [New product launch] EasyNTC Adsorption Needle Aging Instrument, Say Goodbye To The Single Needle Suffering](https://www.smartlabhub.com/image/cache/catalog/222-1140x400h.png)

In the analysis of volatile organic compounds (VOCs), the accuracy and reproducibility of experimental data are always the core concern of researchers. However, many laboratories often face a common challenge in the sample pretreatment stage: the aging effect of adsorption needle directly affects the reliability of subsequent analysis results.

Why must the adsorption needle be aged?

Whether it is a new or reused adsorption needle, aging treatment is necessary. New adsorption needles may contain residual organic solvents or volatile compounds from the manufacturing process, so they need to be aged before their first use. Reused adsorption needles may have incomplete desorption or store adsorbed volatile organic compounds from the air. If these residues are not thoroughly removed, they can desorb during analysis, causing impurities in the chromatogram and affecting the detection of target substances.

Through heating and inert gas (such as nitrogen) blowing, impurities on the surface of the adsorbent are removed, pore structure and active sites are restored, and subsequent sampling efficiency is improved. Residual substances in the adsorption needle are removed efficiently to avoid cross-contamination and reduce baseline noise, so as to improve the accuracy of data.

Conventional aging VS. Specialized aging

The conventional aging method requires the use of GC-MS inlet, which not only increases the cost of helium consumption, but also can only process a single adsorption tube at a time, which is inefficient and seriously affects the experimental throughput.

The dedicated multi-position aging instrument can process 10 adsorption needles at the same time for batch aging, which improves the experimental efficiency several times, reduces the instrument occupancy time and gas consumption at the same time, and helps reduce the cost and increase the efficiency of the experiment.

Method comparison

Contrast items | conventional method | EasyNTC A life expectancy meter |

productiveness | Single needle processing, time and effort | 10 parallel processing, efficiency increased by 10 times |

prime cost | GC-MS is occupied, and helium consumption is high | Independent operation, using nitrogen, saving more than 90% of the carrier gas cost |

consistency | The aging temperature and time of different adsorption needles are inconsistent | The aging conditions are consistent, the human operation error is reduced, and the consistency is high |

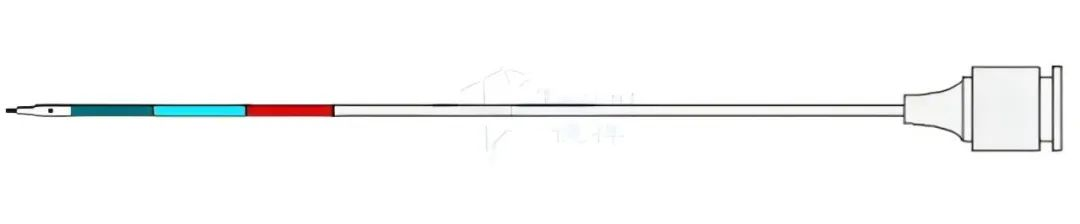

INNOTEG EasyNTC Adsorption Needle Aging Instrument

INNOTEG EasyNTC Adsorption Needle Aging Instrument is an efficient and economical aging solution designed for Needle Trap technology, which can significantly improve the efficiency of experiments and reduce the cost of use.

Product superiority

1. Light weight, only the size of an A4 paper, greatly saving experimental space;

2. Plug-in structure, NTD pins can be loaded quickly without tools, simple and efficient operation;

3. Flexible adaptation, support 1~10 needles to be combined and aged arbitrarily to meet different throughput requirements;

4. Low flow design, full load only needs about 300ml/min, further reduce consumption;

5. PID precision temperature control technology is adopted, which can control the temperature quickly and respond quickly;

Needle Trap (NT) technology is an active dynamic extraction method. It works by filling the needle tip with adsorbent and using a Sampling Case gas sampler to concentrate gaseous samples within the adsorbent inside the needle. By increasing the amount of adsorbent or combining different types of adsorbents, the adsorption capacity can be enhanced, making it suitable for analyzing a wider range of volatile organic compounds.

Say goodbye to inefficient manual operation, and use professional equipment to protect your VOC data!

IF YOU INTESTED IN THIS PRODUCR, PLEASE CONTACT:

5 Comment(s)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Leave a Comment